Contact us

Double end seals include axial double end seals and rad […]

Double end seals include axial double end seals and radial double end seals. The double-face seal structure arranged in the radial direction is more compact than the double-face seal in the axial direction. The double end face seal is suitable for the medium itself with poor lubricity, toxic, flammable, explosive, volatile, containing abrasive particles and gas.

A pair of sealed end faces is a single end face seal, and a pair of sealed end faces is a double end face seal. The single-end sealing structure is simple, easy to manufacture and install, and is generally used under the conditions of good lubricity of the medium itself and permits slight leakage. It is a commonly used type of sealing. use.

The axial double-end face seal has a face-to-face or back-to-back arrangement. When working, it is necessary to introduce a sealing liquid higher than the medium pressure of 0.05 ~ 0.15MPa between the two pairs of end faces to improve the lubrication and cooling conditions between the end faces and isolate the medium from the outside It is possible to achieve "zero leakage" of the medium。

Zhejiang Guolin Machinery Co., Ltd. is located in Taizhou, famous for“Famous Mountain at Sea”, a coastal city in the middle of Zhejiang Province.

Zhejiang Guolin Machinery Co., Ltd.

Get in touch with us via mail phone.We are waiting for your call or message

[email protected]Copyright © Zhejiang Guolin Machinery Co., Ltd. Rights Reserved.

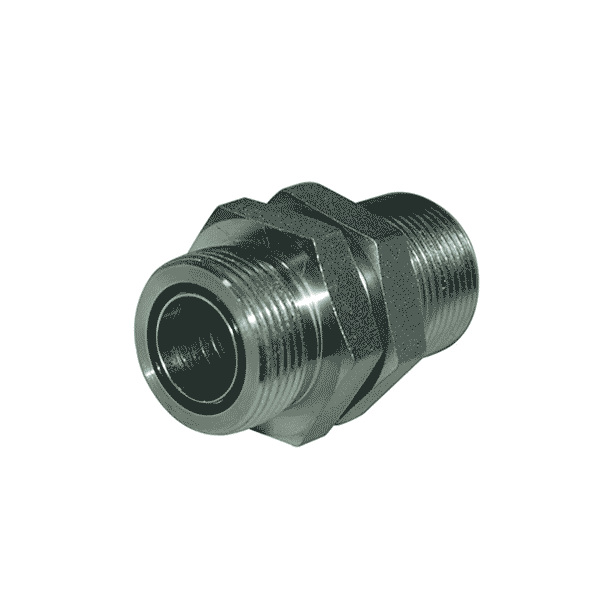

China stainless steel fittings manufacturers hydraulic fittings Factory

Support by: HWAQ