Contact us

The Flat Face Seal is one of the hydraulic fittings, wh […]

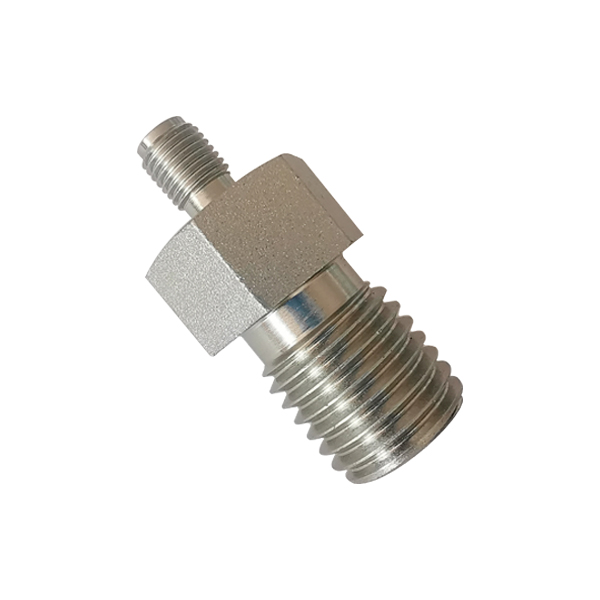

The Flat Face Seal is one of the hydraulic fittings, which play a great role in the construction industry. It is used in every type of industry to seal or prevent the flow of fluids through metal pipe fittings and other forms of connection. It is usually utilized in the case of cold and hot joints where there is a reduction in the diameter of the pipes. There are two types of it, namely; hydraulic and mechanical.

As mentioned above, the Flat Face Seal can be classified into two types based on its design and functioning. The first type of it is called the hydraulic face fitting, while the other one is called mechanical. Both of these fittings have the same principle to seal or prevent the flow of the fluid through the pipe joint but the difference is the mechanism and the materials used to build them. The hydraulic fittings usually use the pressure of the air or gas to perform the task; while the mechanical ones use the force of the pistons or similar tools to do so. The hydraulic fittings are mostly preferred over mechanical ones for their ease of use and the lesser number of parts that are to be integrated to perform the task.

Besides the above mentioned types of Flat Face Seal, there is another type called the Retainer Flap that also performs a similar function. These fittings use metal retainers to retain the form of the pipe or fitting. There are different metals that can be used in the construction of these retainers. The most commonly used metal in the construction of these retainers is the brass. However, they can be made from any other metal as per the requirement of the application.

Flat Face Seal is widely used in the industries to protect or prevent the passage of dangerous gases and liquids, in the case of high temperature applications. This type of sealing ring has an inbuilt sensor to detect the temperature and seal the tubes or pipes accordingly. In case of low temperature applications, the Flat Face Seal is coated with a layer of wax that prevents the impurities from penetrating into the sealing ring. In case of high temperature applications, the Flat Face Seal is fully sealed so that no temperature is able to pass through it. This prevents any harmful gases and liquids from being formed inside the pipe or fittings.

The application of Flat Face Seal is done by removing the old seal and replacing it with the new one. Most of these fittings are available in different sizes and types, depending on the pipe or whatever size you want to fix. You can choose the right type of Flat O-ring face seals that will fit into the pipe or whatever size you have chosen. These can also be matched with your existing seals so that both of you can work well.

Most of the times, you would need to replace your Flat Face O-rings with the Flat O-ring face seals. When it comes to the proper installation, you need to make sure that all your cylinders are in good shape before you replace the old ones with the new ones. If not, your newly fixed hydraulic fittings will not be working properly so it is always better to ask for the help of your captain o-ring manufacturer to do the job.

Zhejiang Guolin Machinery Co., Ltd. is located in Taizhou, famous for“Famous Mountain at Sea”, a coastal city in the middle of Zhejiang Province.

Zhejiang Guolin Machinery Co., Ltd.

Get in touch with us via mail phone.We are waiting for your call or message

[email protected]Copyright © Zhejiang Guolin Machinery Co., Ltd. Rights Reserved.

China stainless steel fittings manufacturers hydraulic fittings Factory

Support by: HWAQ