Contact us

Especially if you are building something that supports […]

Especially if you are building something that supports a substantial amount of weight, such as humans, you will need to use stainless steel fasteners. Steel all by itself can rust until it breaks, and nobody wants that.When stainless steel fastening systems such as nuts and bolts are employed, they tend to meld together. This is due to the chromium layer on the surface of the stainless steel being exposed to oxygen for a short time before fastening. When the pieces are screwed together, the oxygen is taken out of the equation, solidifying the bond. This process is called “galling”.

There are other types of stainless steel fasteners that resist becoming brittle at lower temperatures. These stainless steel screws are infused with nickel. The nickel also works to de-magnetize the stainless steel. Manganese can also be used in place of, or in cooperation with, nickel, to roughly the same effect, but at a lower cost.China 45° elbow tube Suppliers can also be used to reinforce the steel compound. When subjected to heat, these fasteners can become hardened and strengthened to create finer elements, like the point of the screw, as well as the threads.

Depending on what your fastening needs are, you will be buying different types of stainless steel fasteners for different fastening jobs.Here’s an interesting side note: stainless steel has a long history. The first non-corrosive object still currently in existence is an artifact from India called the Iron Pillar of Delhi, which was a high-phosphorous-content iron pillar. Modern stainless steel was invented in the early part of the 20th Century, by a number of inventors and researchers simultaneously. The first stainless steels were made of 10-18% chromium, along with significant amounts of carbon. Thanks to these inventors, stainless steel fasteners became a very widespread, low-cost reality.

Zhejiang Guolin Machinery Co., Ltd. is located in Taizhou, famous for“Famous Mountain at Sea”, a coastal city in the middle of Zhejiang Province.

Zhejiang Guolin Machinery Co., Ltd.

Get in touch with us via mail phone.We are waiting for your call or message

[email protected]Copyright © Zhejiang Guolin Machinery Co., Ltd. Rights Reserved.

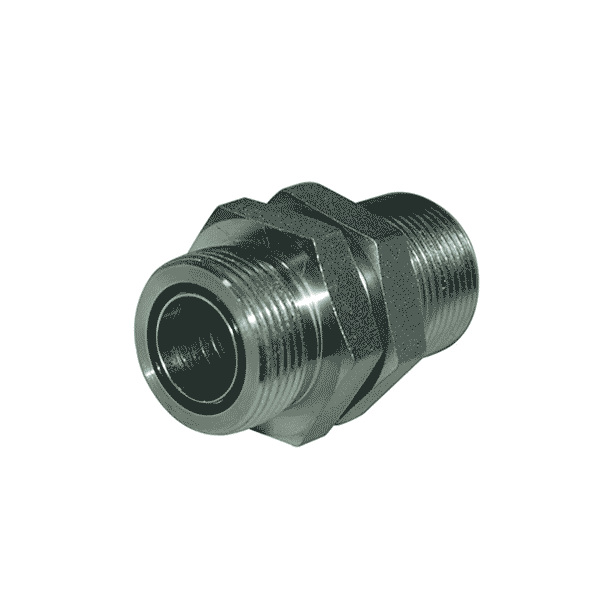

China stainless steel fittings manufacturers hydraulic fittings Factory

Support by: HWAQ